Multi – Material Packaging

ICA manufactures a wide range of multi-material industrial packaging solutions, either custom designed by our team or specified, to fit our customer needs.

We use our 30+ years of experience to provide integrated packaging products tailored to the specific products you manufacture, how your product is transported, your material handling, and your storage needs. We provide industrial manufacturers with cost-effective integrated packaging solutions that are customized to fit your product, and designed to optimize your supply chain. We know that integrated packaging solutions require a deep understanding of your needs and a clear definition of the challenges you’re facing. Our comprehensive approach to integrated packaging solutions allows us to customize packaging and service programs that achieve long-term cost control. Very often, choosing the right integrated packaging products made with the right materials can make all the difference in the total cost of your solution, and the right products definitely help reduce the cost of in-transit damage.

Specs

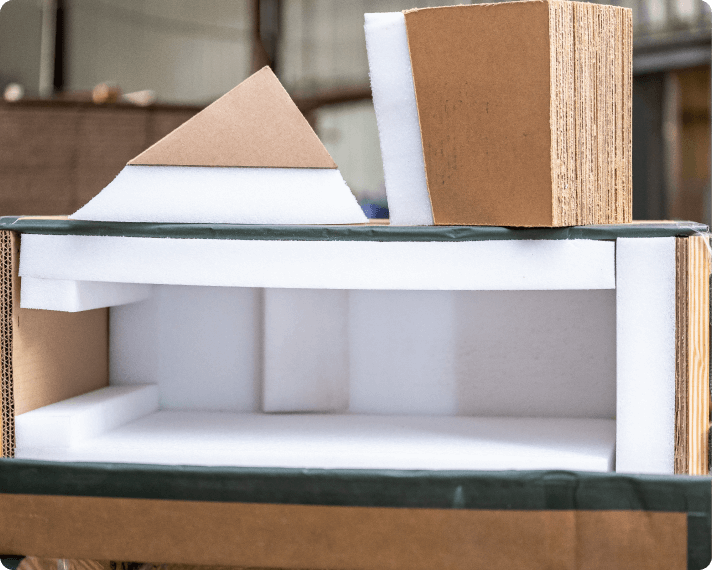

When designing integrated packaging, there are a wide variety of packaging materials that can be used to help protect your manufactured products in transit. ICA works with all these materials directly, that is one of the differences you’ll get when working with us. ICA is not a packaging distributor, we are a packaging manufacturer, we manufacture almost everything we sell.

Materials issues in our multiple material integrate packaging.

Wood – Wood plays a prominent role in an integrated packaging solution. Sometimes it’s used as the foundation for the rest of the packaging as a pallet, crate, skid, or container, while other times wood is used for bracing, supports, dividers, etc.

Corrugated and Paper – Paper and corrugated paper are used in a wide variety of integrated packaging solutions, from cardboard cartons to wrapping for sensitive products. Cardboard and paper are most often used as fitments, dividers, slip sheets, boxes, cartons, trays, and hoods.

Foam – Foam is very common in integrated packaging because it does such a great job of protecting products. While there are different types of foam used in packaging, foam is nearly always used as fitment, corner/edge protection, and cushioning.

Steel – Steel is mainly used for connection, exterior protection, or closure. Custom brackets, corners, edges, reinforcing structure, hinges, handles, hasps, latches, reusable fasteners are all examples of what steal item ICA would use in a design.

Plastic – Plastics are a versatile part of many different types of integrated packaging. It’s not unusual to see them in corrugated sheets, bags, bins, boxes, banding/strapping, zip-ties, wrapping, and films.

Superior Service

ICA is built on service. As a partner, we work tirelessly to meet all of our customer needs.

Unmatched Quality

Expert Design

ICA is focused on solutions. Our expertise puts your packaging solution in the most knowledgeable hands.